Non classé

Promotion and clearance

Variable speed screw compressors IE4

Screw compressors

Complete station

Spiral compressors

Piston compressors

Tanks, Purges, Valves

Air dryer

Filtration

Maintenance kit

Energy saving

Consumables

Sécheur par adsorption

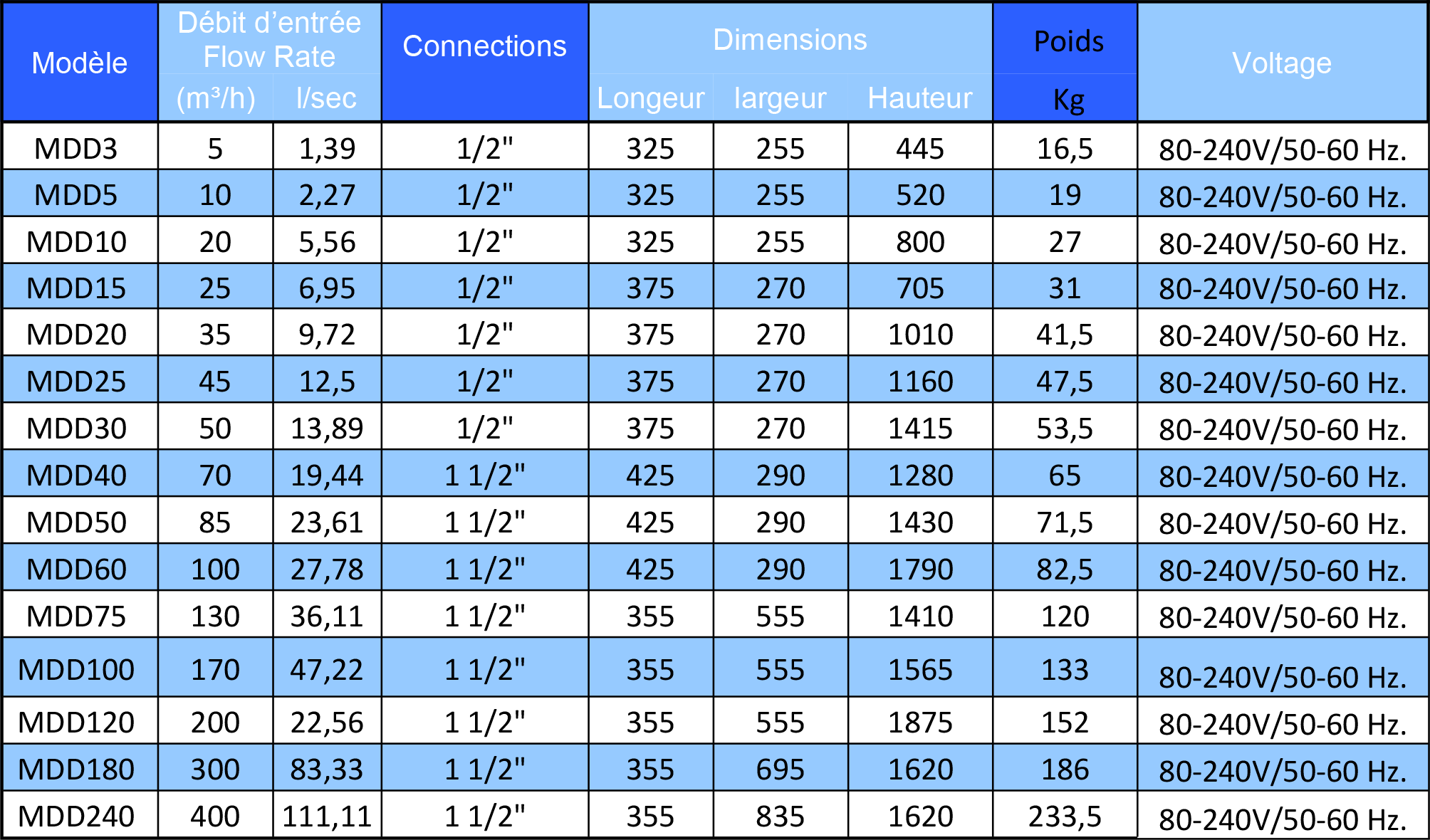

MDD 30 à MDD 240

The modular and lightweight design of the new dryers brings a whole new concept in compressed air technology, offering total installation flexibility to meet specific needs.

The MDD dryers are delivered with 3 filters, 2 to be installed upstream of the device. (grade 1 micron + grade 0.01ppm), the last to be installed at the outlet of the air dryer intended to recover desiccant dust.

-

MDD 3 dew point – 40°C flow rate 5 M3/H

2050.00 €Availability - contact usAdd to basket -

MDD 5 dew point – 40°C flow rate 10 M3/H

2190.00 €Immediate availabilityAdd to basket -

MDD 10 dew point – 40°C flow rate 20 M3/H

2400.00 €Availability - contact usAdd to basket -

MDD 15 dew point – 40°C flow rate 25 M3/H

3050.00 €Availability - contact usAdd to basket -

MDD 20 dew point – 40°C flow 35 M3/H

3250.00 €Availability - contact usAdd to basket -

MDD 25 dew point – 40°C flow rate 45 M3/H

3320.00 €Availability - contact usAdd to basket -

MDD 30 dew point – 40°C flow rate 50 M3/H

3680.00 €Availability - contact usAdd to basket -

MDD 40 dew point – 40°C flow rate 70 M3/H

4400.00 €Availability - contact usAdd to basket -

MDD 50 dew point – 40°C flow 85 M3/H

4500.00 €Availability - contact usAdd to basket -

MDD 60 dew point – 40°C flow rate 100 M3/H

4780.00 €Availability - contact usAdd to basket -

MDD 75 dew point – 40°C flow 130 M3/H

5843.00 €Immediate availabilityAdd to basket -

MDD 100 dew point – 40°C flow rate 170 M3/H

6070.00 €Availability - contact usAdd to basket

The compressed air dryers of the MDD range are designed to remove moisture using the appropriate technology to obtain dew points under pressure from -40°C to -70°C (optional, consult us)

A Crouzet dew point tipping is also available as an option at the unit price of €1,280. This process makes it possible to achieve considerable energy savings and lower operating costs, avoiding any waste of regeneration air during compressor downtime.

The dryers in the MMD range require a minimum of maintenance and can be installed virtually anywhere.

The dryers in the MMD range are composed of an upper and lower part between which is an extruded aluminum part and composed of two chambers. The upper part includes the air inlet and outlet collectors. The lower part consists of two exhaust solenoid valves and a ball-inverted valve. In operation, one chamber is in line (drying phase) while the other is in regeneration. This technique is more commonly called PSA (Pressure Swing Adsorption – Adsorption by Pressure Variation).

Adsorption by pressure variation (PSA)

A small percentage of dry air is taken at the exit of the dryer and is used to regenerate the saturated chamber. This dry air relaxed at atmospheric pressure physically removes moisture from the regeneration chamber and is evacuated through the exhaust valve.

+33 1 64 44 14 91

+33 1 64 44 14 91 My account

My account  My cart

My cart